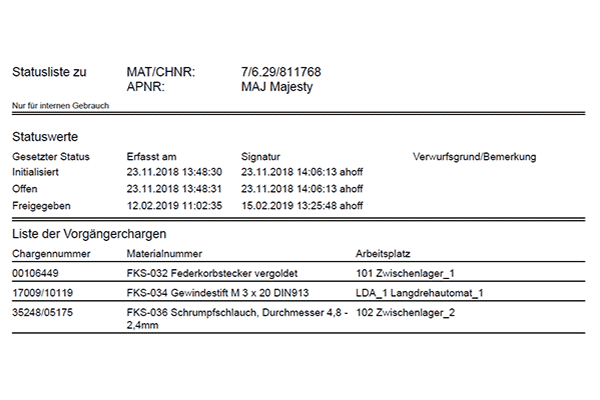

Traceability within seconds and focusing on all existing predecessors allows unlimited tracking and tracing in vertical and horizontal planes. All special features recorded during the process can be recognized by all employees at any time by means of a conspicuous characteristic.

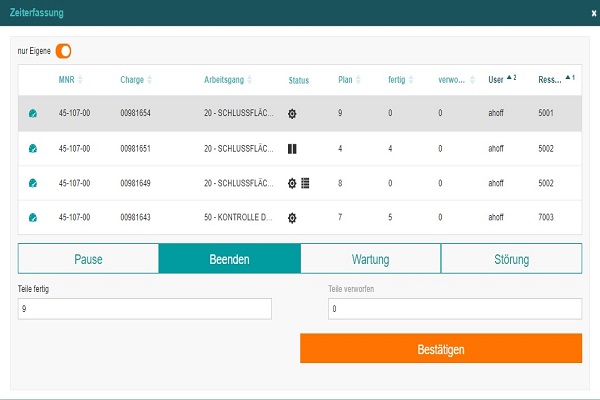

Up to now, terminals have mostly been available in the production halls for time recording. Routes between the own workplace and the terminal cost time and disturb the work flow of the employees. With mobile time recording in DOQ, every process step is recorded precisely directly at the workplace and is available for reliable post-calculation. “Set-up", "lying down" or "production" times can be started with a single click. When ending the time recording, entries can also be made in the mask for good parts / scrap.

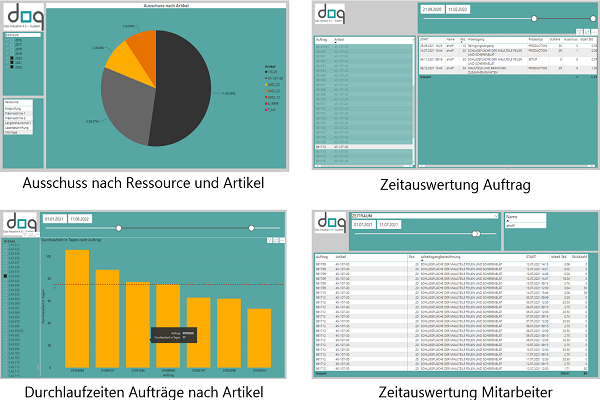

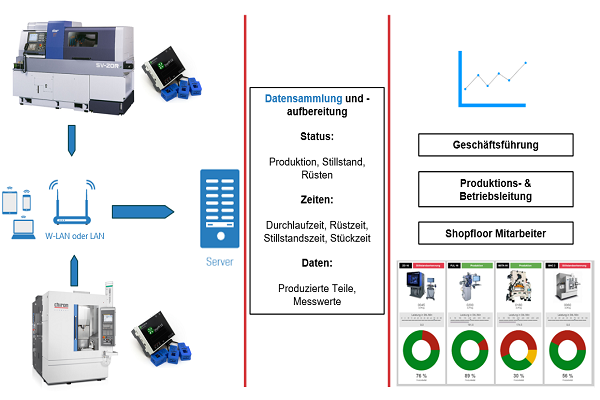

All existing database entries can be evaluated time-controlled or on-demand across process chains and visualized in individual dashboards. With the stored target times from the article master data of the ERP and the actual times recorded by DOQ, a variety of analyses can be performed with filter settings regarding agents, articles, resources, operations and time intervals. The adjustment of target times to practical values not only increases planning reliability for the lead times of individual articles in the long term, but also enables more accurate post-calculation. Quality analyses of scrap quantity, reason for scrap and scrap frequency can also be created. Due to the output as csv. files, all DOQ analyses can be further processed in BI systems and prepared into meaningful dashboards for all company levels.

Die gesamte Herstellungsdokumentation aller gefertigten Chargen oder Medizintechnikgeräte wird von DOQ als papierlose Produktentstehungsakte im PDF/A Format zur Verfügung gestellt. Die konfigurierbare Archivdatei kann sowohl Informationen zu Vorgänger Chargen als auch alle Audit-Trail Aufzeichnungen und Signaturen enthalten. Über eine Dokumentenliste können auch Prüfberichte, Fotos, Materialbescheinigungen oder andere Dokumente als Bestandteil des eDHR definiert werden. Mit einem übersichtlichen Inhaltsverzeichnis versehen lässt sich dieses Dokument auch für Kundenzwecke nutzen.

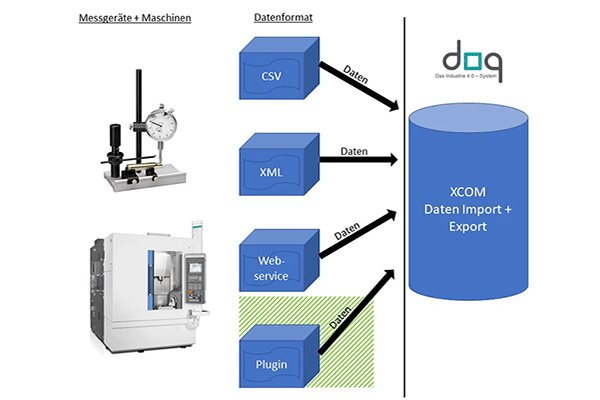

X-COM is the application for automated data exchange between external data suppliers and DOQ. Data formats from web services, XML or Excel files can be processed directly. If machines or measuring devices provide other data formats, these are interpreted by an individual plugin for X-COM processing. Raw data is filtered in the plugin for meaningful content and then made available to X-COM. By configuration, a corresponding schedule for data transport can be defined, but when using a web service, the data can also be imported on demand. For the connection to SAP, the structured data transfer is executed by SAP IDoc. The control record, data record and status record are created using structured data transfer via XML.

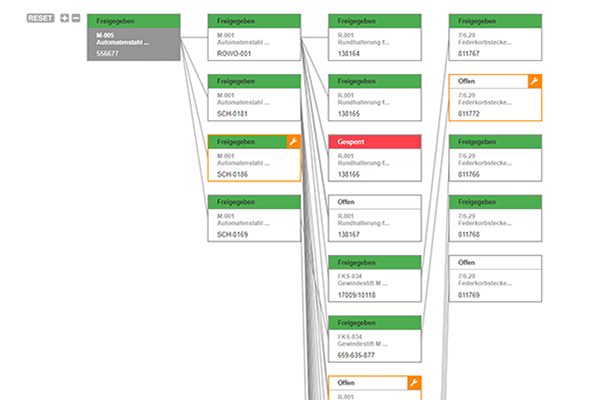

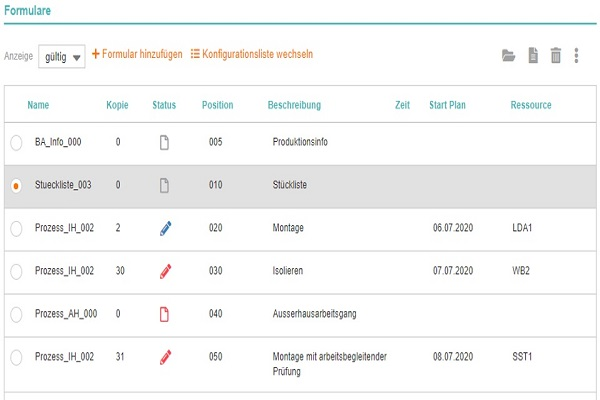

The clear display of the process steps allows a quick overview of the production status of the individual batch. After opening the forms stored in each process step, the individual steps can be edited. It is possible to include individual blocking steps in the process, for example, due to checks. The configuration of a status workflow enables individual process steps to be released only according to the dual control principle.

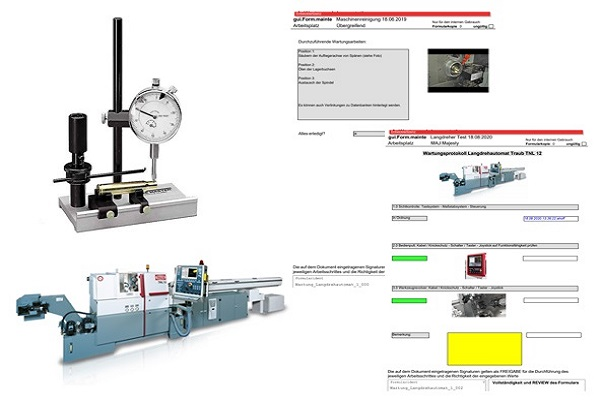

Maintenance planning in DOQ enables the user to obtain information at his workstation about upcoming maintenance for machines, measuring instruments or other equipment. The planning can be time-controlled or based on the number of usages/quantities. The system has a notification function for stored recipients by e-mail or SMS. The complete maintenance history can be viewed at any time in the maintenance cockpit.

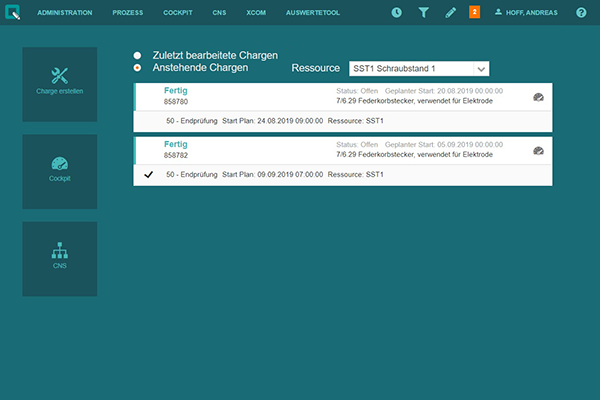

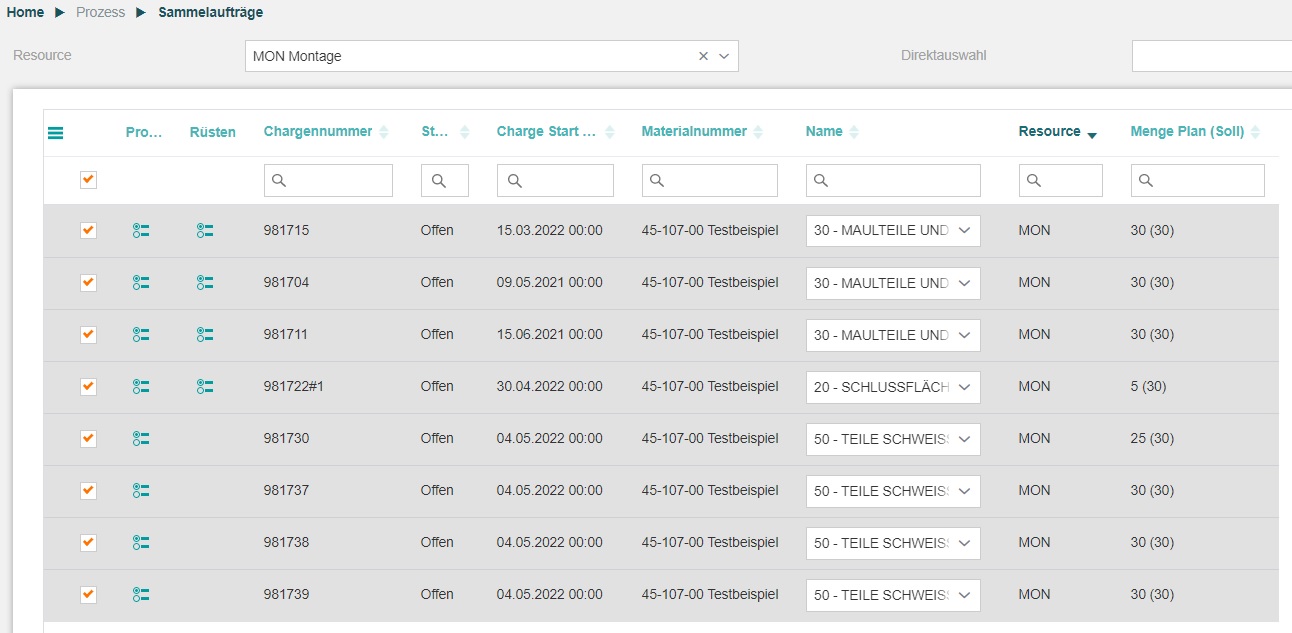

The detailed planning in DOQ for the employees and machine occupancy of various work processes can be realized both with a connected control station and with directly stored start dates from the ERP. If a control station is used, the current planning is transmitted to DOQ every 5 minutes. Possible changes in the work sequence are updated, filtered and made available to the employees in a resource-related manner. DOQ also offers the option of carrying out your own detailed planning by drag and drop. Here, work orders in ERP are only planned at group level and in DOQ are assigned to individual employees or machines by the production management.

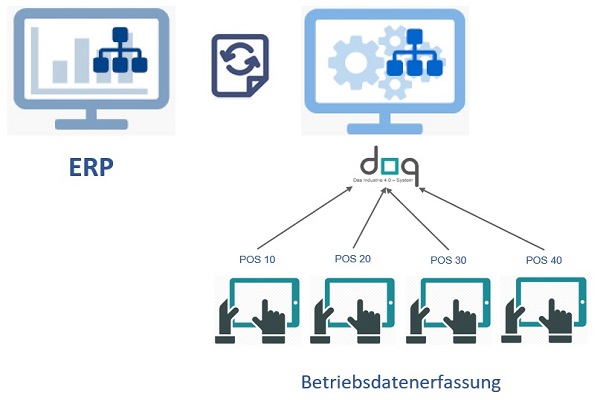

In addition to the process times for "set-up", "production" and "lying" processes, all partial and finished messages with details of the produced scrap for individual work steps belong to the PDA recording. Further confirmations can be scanned batch numbers of parts list items or maintenance tasks. Due to the digital recording of the data, they are available to the entire company at any time and thus increase transparency.

With the help of XCOM or an OPC-UA client server, relevant machine data such as current statuses (setup, production, production interrupted, production finished), currently produced quantities (counter), and current piece time / cycle rate can be transmitted. These data are made available to the operator in DOQ at each connected machine and sent in parallel to the control station, if available.

The option of creating collective orders for operations such as cleaning, hardening or coating saves time when filling out the digital forms. Once compiled, a collective order can also be stamped on again by other employees. It is configurable, for example, whether the recorded times are completely assigned to all operating orders or whether they are divided according to the number of batches and quantities.

A simple but incredibly useful feature is capturing photos with the tablet camera. Whether it's for documenting defective parts at receiving, proving a nameplate is attached to a piece of equipment, or describing scrap defects, the photo is right there on the store floor where it belongs. The photos are automatically converted to a PDF and are part of the eDHR.